Why TRES

ぜひご覧ください。

JAPAN QUALITY世界に誇る、ソファメーカーを目指して

常に目指すのは、世界の高級ブランドと肩を並べる「日本一のソファ」。TRESは、母体であるT’s mobile(ティーズ・モービレ)が創業以来17年に渡り培ってきた技術と、首都圏を中心としたライフスタイルショップへのOEM供給、そして、これまで約4万台のソファを全国のお客さまにお届けしてきたという実績を活かし、企画デザインから製造出荷に至るまでの全工程を自社工場で行っています。さらにTRESのソファは、イタリアで習得した技術と豊富な経験により、ソファづくりを熟知した専門のデザイナーが全商品のデザイン設計を担当。外からは見えない内部のパーツにまで最高級素材を使用するなど、デザイン性、座り心地、耐久性を兼ね備えた、国内最高水準のクオリティを誇ります。

COMFORTABLE人生を変える、感動の座り心地

座った途端、心がほどけていくような感動の座り心地。これを実現するために、触感を左右するクッション材にも最上級素材を惜しみなく使用しています。密度の異なる数種類のウレタンを積層することで身体をしっかりと包み込み、底付き感がないため、一日中座っていても疲れません。さらに、高級羽毛布団にも使われるハンガリー産マザーグースのスモールフェザーが、触れた瞬間の柔らかなファーストタッチを実現。ソファの上で、大切な人と心からリラックスして過ごすやさしい時間、人生における特別なひとときを演出します。

MASTERPIECE一脚のソファが生まれるまで

堅固で、混じりけのない、一本の木。確かな眼でそれを見つけることから、私たちのソファづくりは始まります。全体重をかけて身体を預けられる唯一の家具であるソファは、耐久性が命。そのため、土台となるフレームには強度に優れた「天然無垢材」を使用しているほか、すべてのパーツに厳選した素材を採用。全工程を卓越した職人技で仕上げることで、高品質を追求した「一脚のソファ」が完成します。さらに搬入やメンテナンスなど、ビフォー・アフターサービスにも徹底的にこだわり、一生もののソファとして永くご愛用いただくための万全のサポート体制を整えています。

Making Process

Framing木工・組立

山や森で育った天然の原木から切り出され、通常はテーブル天板などの表面材に使われる「天然無垢材」をフレームの素材として贅沢に使用。人の手を加えていない無垢材が持つ独特のゆがみを調整しながら、細部にまで丁寧な加工や組み立てを施すことで、強靭な構造体をつくり出しています。

Webbing Tapeテープ張り込み

サイズ、デザイン、座り心地に合わせてテープを張り込む

間隔と張度を計算し、それぞれのソファに最適な張り込みを行います。

イタリア製最高級ウェビングテープを一本一本密に張り込むことで、

ずっしりと重い高密度ウレタンを支える頑丈な土台が完成します。

Urethaneウレタン切断・接着

座面、背もたれ、アームレストなどそれぞれの

パーツに合わせたサイズにウレタンをカット。

完成した土台に、柔らかく扱いづらいウレタンを一つひとつ

手作業で丹念かつスピーディーに接着します。

TRESのソファは高密度ウレタンを使用しているため、

経年劣化に強く、耐久性に優れています。

Fabric裁断・縫製

パタンナーが製作した型紙に合わせ、

イタリア直輸入の高級ファブリックを裁断。

生地によって自動裁断機と手作業での裁断を使い分けています。

パーツごとに裁断したすべての生地に生地端のほつれ防止処理を行い、

経験豊富な職人が手作業で一枚に縫い合わせます。

その後、ステッチやパイピングが施され、

ファスナー開口部などに特殊補強縫製が行われます。

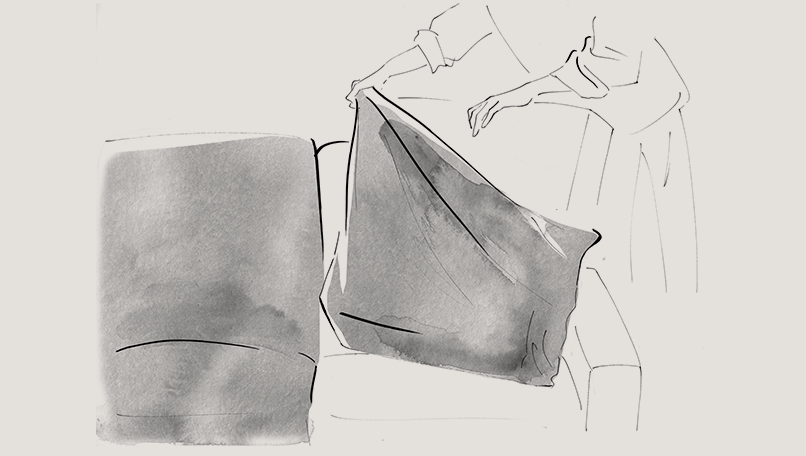

Finishing仕上げ

「カバーリング」と呼ばれる、

ウレタンが接着されたフレームに完成したカバーを被せる仕上げの作業を行い、

一脚のソファがついに完成します。

そして厳しい品質チェックの後、梱包を経て、

TRESのソファはお客さまのもとへ届けられます。

Maintenance / Aftercare

永くご愛用いただくためのパーツ交換・修理・保証

TRESでは、製品を一生もののソファとして永くご愛用いただくために

保証年数を設定せず、ご満足いただけるまで対応させていただきます。

これまで約6万台を出荷したなかで、フレーム破損のご報告は0件と品質には

絶対の自信を持っておりますが、お困りのことがあればいつでもご相談ください。

※すべてのメンテナンス・アフターケアが無償というわけではございません。

-ソファの経年劣化が気になり始めたら、

お気軽にスタッフにご相談ください-

- クッション内部のウレタン交換

- クッション内部のフェザー打ち直し

- クッションのカバー交換

- ソファ全体のカバー交換(*)

- 座り心地の調整

季節やお好みに合わせて自由に衣替えいただけます。

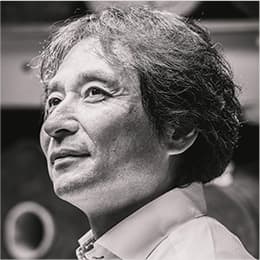

Designer

道畑 拓美Takumi Michihata

1963年石川県生まれ。

1986年武蔵野美術大学造形学部基礎デザイン学科卒業。

卒業後、大手家具メーカーデザイン部を経て

在日米軍基地内施設の建築設計に携わったのち、

1992年石川県にUターンし某家具メーカーに企画開発室室長として入社。

同年イタリア留学にてインテリアデザインを学ぶ。

在籍中はオリジナルブランドの立ち上げや

イタリア高級ソファメーカーのライセンス事業に携わる。

2000年に独立し、代表の越村と共にT’s

mobile創業。

以降、ソファ専門デザイナーとして

自社ブランドにおける全商品のデザインを手掛ける。